I'm running short on time recently so to start with heres a picture collection from my k26/k27 hybrid install.

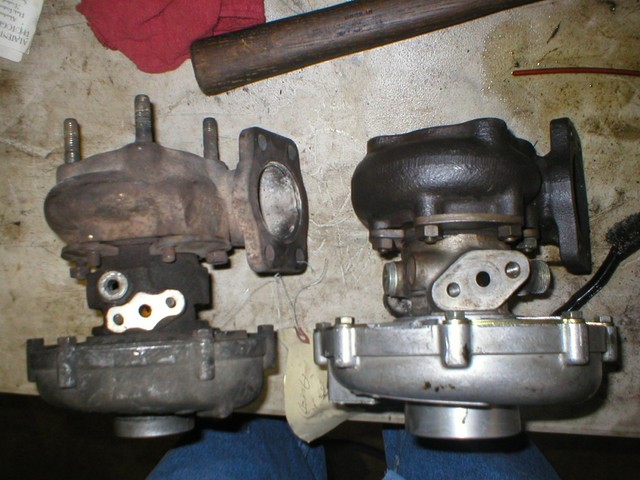

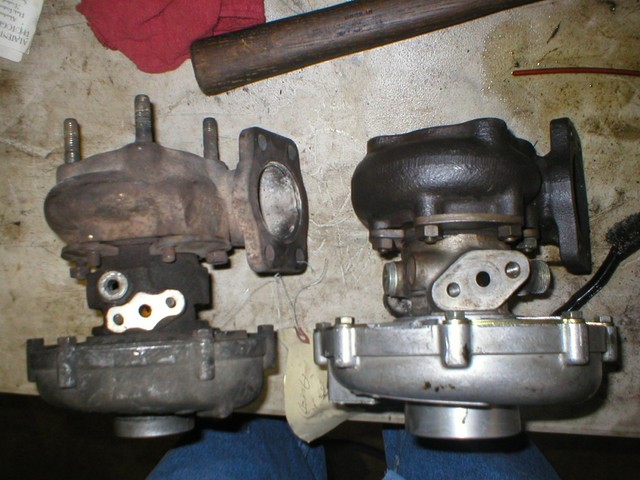

I was havingf trouble with the stock K26 not flowing anywhere near what I needed, so I knew I needed an upgrade in order to make any more power. With the k26 if I went WOT in third gear I would have 2.0bar by 2500rpm, 2.4bar by 2700rpm, but arround 4000rpm it would start dropping all the way down to 2.0 again. Also intake air temps would get really high since I was running that turbo waaaayy outside its efficiancy range (off the compressor map even). I knew I didn't have the money for what I really wanted, which is a T3/T4 hyrid, but one day while trying to teach somebody how a turbo system worked I found this K27/K26 hybrid sitting on a shelf. Needless to say, I was pretty happy, and even more happy when I checked the end play (none) and side play was well within spec. The issue came in though that the k26 core was setup for a Porsche 944 Turbo meaning it had side input water fittings instead of top/bottom like the Audi k26, and the oil flanges were a bit different. In these pictures you can see the differeance:

Here you can see the size differance of the business end. 62mm inlet of the k27 (right) vs the 46mm k26.

Size of the oil inlet on top is significant, through the actual hole diameter is just about the same.

Side water inlet rather then top.

My method of making templates for flanges. I got a small piece is paper and some touch up paint, painted up the area where the flange would bolt to, then stuck the paper on to the flange area. Works every time!

The obvious fix for the oil and water line problems has AN written all over it! First things first I made a flange for the oil inlet. Then I got ahold of all of the AN fittings and hose I needed. I used Starlite (kevlar/nomex braided instead of Stainless steel, $15 a foot!) hose for both inlets because the stainless is more likely to absorb heat from outside and transfer it into the liquid. Also the Starlite is much nicer to work with. When it came time to make the flange for the oil output side I noticed that it looked familiar. Then I too a look at my spare engine in the stand and noticed that the OEM oil out line, while different on the turbo side, is the identical flange where it bolts to the block. Simple solution to that, I cut the flange off a spare OEM Audi oil outlet hose and had planned to braze it on to a second OEM outlet line to make one that had the larger flange on both ends. Then one of my mechanics suggested he would rather torch weld it with steel then have me braze it (I'm good with brazing, not with steel). I figured I'd watch him do it and learn. Turns out he wasn't as good as he thought, and it came out working out ok as far as not leaking, but it doesn't look pretty. Good enough I suppose. Oh and do yourself a favor and try to find some krylon Chrome paint, thats what I used on this line and it looks great! I had to take the oil filter adapter off (the hunk of alum. that bolts to the block and feeds oil through the filter, and to the turbo and oil cooler) and punch out the hole that delivers oil to the turbo, then I installed an AN -6 fitting into the hole and re-installed the assembly. The flange that I made for the turbo got coated with some gasket glue and bolted on after I installed another AN -6 fitting in it.

Then one Friday I took the old turbo off and fitted the new one. From there it was easy as pie. I had to figure out the route of a few lines, then cut them and installed the coresponding AN fittings. I used to Goodridge heat insulation on the water input because it has to run pretty close to the header and some other hot stuff.

The black hose you see is the StarLite Kevlar/Nomex braided stuff that I snagged. It's awseome hose, every bit as strong and durable as the regular stainless braided, but a TON lighter (and I mean this is super lightweight stuff!), and easier to work with. Also it wont cut a hole through anything that it may possibly rub against.

The water output here runs arround the frame rail and then back to the block. I was going to use a 90 degree fitting and send it down next to the turbo and arround, but this routing is much smoother and out of the way.

Here you can see the Goodridge insulation which is protecting the water input, and the oil input.

Slightly different angle of the side with no wires in the way.

Clear view of the flange I made for the oil input.

Doesn't that thing look awesome sitting in there with no grill on the car?! Yes the rubber front engine mount is off for a reason, I replaced the motor mounts at the same time as the turbo and needed to lift the engine a bit which that mount wouldn't allow me to do.

This is slightly different routing of a few lines, I set it up this way at first then changed to the above routing.

Oh yeah, I forgot to mention, new wheels!

Old wheel for comparison.

Me.

Then it was time for the fun part, testing. After I got the intake manifold back on and the car fully buttoned up I ran the engine for a while (new oil and filter was done first actually) to check for leaks, none found except some drips from me spilling oil while filling it up. After that I went arround the block about 10 laps slowly and came back in to check again for leaks, still non. Then for the exciting part. I went to a larger road and did about 5 1.3 bar boost runs (boost knobs set to 0, but wastegate spring kept it to 1.3bar pressure) to get it warmed up a bit, then turned it to 2.0, everything ok, car pulling great, so after another 5 3rd and 4th gear runs I went up to a full 2.4bar. Wow. It pulls great all the way to 7000rpm (and beyond), if I want it to, though I still usually shift nearer to 6000rpm. Intake temps are staying lower now too because this turbo is nearer its efficiancy range, though I haven't yet recieved the copmressor map I ordered from 3k-Warner in Germany. Lag is worse yes, but not bad really. I recently raced and won against a customer in his Porsche 928S4 so I'm fairly confident in the changes! Now I need a header and intercooler.....well hmm I do havfe a 10x16x2.75 intercooler core laying here.... More on that soon!